المنتجات الساخنة

Analysis of vertical roller mill performance with changes in material

网页2022年5月31日The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries. In this study, the discrete element

Contact

Vertical Roller Mills

网页Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your

Contact

Vertical roller mill for raw Application p rocess materials

网页Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation

Contact

Modeling and simulation of vertical roller mill using population

网页Abstract: There are few studies concerning the process simulation of vertical roller mills (VRMs). In this research work, the application of population balance model for simulation

Contact

Holderbank Cement engineering book Archive

网页mill has to be calculated e.g. through a heat balance. The maximum admissible mill inlet temperature is < 450 [C]. Gas speeds: The mill has to be sized to meet the required

Contact

Chapter Six: Some Operating Guidelines Vertical Roller Mill

网页2022年4月6日An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill. The largest

Contact

Vertical Raw Mill Heat Balance Solution PDF Scribd

网页In a vertical roller mill the % of false air is usely between 5 and 10%. 330000 Nm3/h on wet. Gas coming from the kiln 270C. 307230 Nm3/h on dry. %.

Contact

VRM HEAT MASS BALANCES SHEET Page 1 of 18

网页i need to know what the method for calculate heat and mass balance of vertical roller mill with capacity 400TPH(.5%MOISURE) and kiln capacity 4500TPD 31 posts. Time Posted 27/12/2010 20:40:36. Ahmed says. VRM HEAT MASS BALANCES SHEET. Send me your E Mail ID, I will send the Excel Sheet . and also the technical details of your VRM

Contact

Chapter Six: Some Operating Guidelines Vertical Roller Mill

网页2022年4月6日An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill. The largest grain mills used worked a

Contact

Vertical Roller Mills

网页As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs. The high energy

Contact

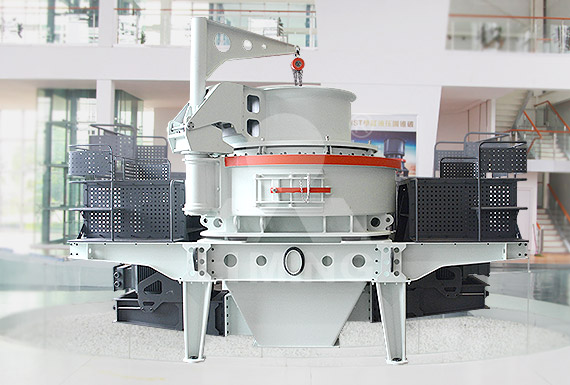

Vertical Roller Mill Operation in Cement Plant

网页The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.

Contact

Holderbank Cement engineering book Archive

网页The vertical roller mill is the appropriate equipment for grinding and drying of wet materials. mill has to be calculated e.g. through a heat balance. The maximum admissible mill inlet temperature is < 450 [C]. Gas speeds: The mill has to be sized to

Contact

(PDF) ANALISIS EFISIENSI PERALATAN DAN HEAT

网页2022年7月11日From the data on this article concludes that the Vertical Raw Mill has a heat efficiency of 90,09% with a heat loss 9,91% which indicates that this equipment is stillefeective to use because its

Contact

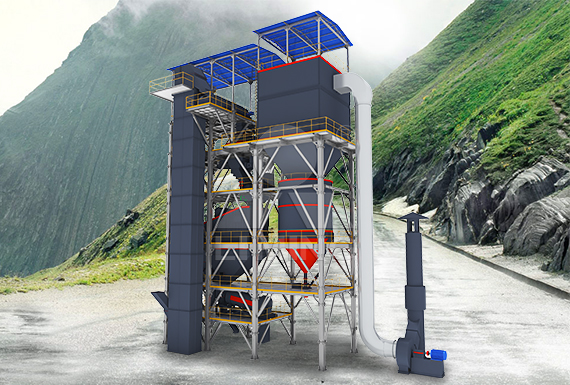

Energy-Efficient Technologies in Cement Grinding

网页2016年10月5日Vertical roller mills are developed to work as air-swept grinding mills. Roller mills are operated with throughput capacities of more than 300 t/h of cement raw mix (Loesche mill, Polysius® double roller

Contact

Optimizing Raw Mills Performance ; the Materials

网页2019年6月22日Limestone 11.30,Shale 16.40 ,Bauxite 9.45,Gypsum 8.16, Silica Sand 16.46,Iron Ore 15.44,Sand stone 11.53Dolomite 11.31. * It may please be noted that the HGIBond Work Index for a

Contact

Vertical Raw Mill Heat Balance Solution PDF Calorie Gases

网页Save Save Vertical-Raw-Mill-Heat-Balance-Solution.xls For Later. 0% 0% found this document useful, Mark this document as useful. In a vertical roller mill the % of false air is usely between 5 and 10% 330000 Nm3/h on wet Gas coming from the kiln 270°C 307230 Nm3/h on dry Gas temperature 100°C % th/h % CO2 26.1

Contact

heat balance in vertical roller mill

网页2017年12月19日Vertical Roller Mills FL Vertical roller mills offer supreme grinding with high energy-efficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertly-designed vertical roller mill (VRM) product range.

Contact

heat balance in vertical roller mill

网页heat balance of grinding mill unit csbsvm Heat Balance In Vertical Roller Mill. Heat balance grinding in ball mill heat balance grinding in ball mill anakanakliesette nl fl ball mill for cement grinding 12 7 the fl ball mill is designed for grinding of clinker gypsum and dry or fl ball mill 4 6 2 3 1 1 stationary inlet 2 mill shell with welded in slide rings and circuit with

Contact

VERTICAL RAW MILL Archives INFINITY FOR CEMENT EQUIPMENT

网页Vertical Raw Mill Heat Balance Excel Sheet. Vertical Raw Mill Heat Balance Excel Sheet To Download the Below Excel sheet + most Important Cement Books and Guides from Famous companies click here now PROCESS FILES VRM HEAT AND MASS BALANCE FLOW MEASUREMENTS BEFORE MILL IDF BEFORE MILL AFTER MILL

Contact

Full text of "Holderbank Cement engineering book" Archive

网页FUNCTIONS OF THE ROLLER MILL The vertical roller mill fulfills 4 main functions in one compact piece of The required gas flow rate through the mill has to be calculated e.g. through a heat balance. The maximum admissible mill inlet temperature is < 450 [C]. Gas speeds: The mill has to be sized to meet the required speed ranges

Contact

Roller Mill: Components, Designs, Uses, Advantages

网页2022年11月30日Advantages of Roller Mills. 1. Produce more uniform, fewer fines, and oversized particles when it comes to product quality. 2. Generates less heat (0 3 0 C) unlike hammer mill that generates up to

Contact

Modeling of energy consumption factors for an industrial cement

网页2022年5月9日The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company from Germany).

Contact

3 Most Watched Questions And Answers About Vertical Roller Mill

网页2021年8月27日Therefore, a relatively small medium can be added to the mill to increase its grinding area by 3 times compared with the ball mill with the same load. 2. How Does The Grinding Function Of The Vertical Roller Mill Produce? The grinding action of the vertical roller mill mainly occurs in two areas, one is the area on the spiral blade, and

Contact

Modeling and simulation of vertical roller mill using

网页There are few studies concerning the process simulation of vertical roller mills (VRMs). In this research work, the application of population balance model for simulation of a VRM in a cement clinker grinding circuit was

Contact

Cement grinding Vertical roller mills VS ball mills

网页Vertical roller mills and ball mills represent two clearly distinct technologies. However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties

Contact

(PDF) EVALUASI KINERJA VERTICAL ROLLER MILL

网页1999年4月18日Key word : Vertical cement mill, mass balance, heat balance . PENDAHULUAN . Dalam pengertian umum, Roller pada vertical mill berfungsi sebagai media penggilingan material ke meja.

Contact