المنتجات الساخنة

Life cycle impact assessment of metal production industries

网页2021年5月12日 The results showed that metal production generates a range of gaseous and particulate matter (PM) emissions during metal and mineral processing (i.e.

Contact

Applications of crushing and grinding-based treatments for

网页2022年12月1日 Induced by the direct input of mechanical energy, crushing and grinding can modulate the target solids via different modes of mechanical actions, including

Contact

Research into the crushing and grinding processes of

网页mechanical crushing and grinding of iron ore under production conditions has been proven. A patent of Ukraine for a jaw crusher design implementing simultaneous impact of

Contact

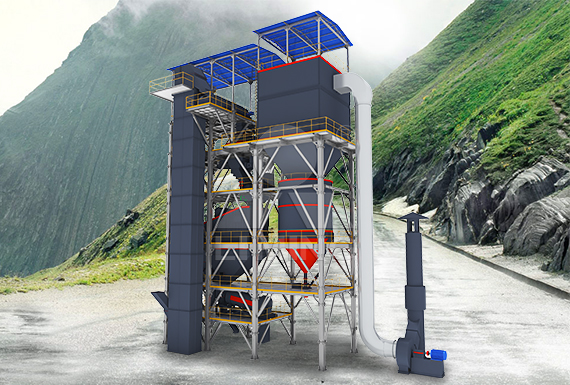

Production Base-mpl Industrial Technology Group

网页2023年7月6日 Production Base. mpl, the leading enterprise of Chinese crushing and grinding industries, has always been dedicated to the development of ore crushers, sand

Contact

Crushing and Grinding Process JXSC Machine

网页2019年10月8日 1. Crushing and grinding improvement. The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the

Contact

(PDF) The Effects of Blasting on Crushing and

网页2003年1月1日 The effects of blasting on crushing, grinding efficiency and energy consumption are discussed. The size of fragments is important in crushing as it effects production and downtime.

Contact

The Evolution of Crushing and Grinding: Changes in the Industry

网页2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years. These adjustments have focused on lowering costs and increasing

Contact

Publication Grain Crushings and Co-Products Production

网页11 行 The report covers dry and wet mill consumption of agricultural commodities and production of products and co-products. Frequency of Release:Monthly. Upcoming

Contact

Crushing and Grinding IndustrialEngineering Chemistry

网页You have not visited any articles yet, Please visit some articles to see contents here.

Contact

Sodium saltpeter crushing and grinding

网页2023年2月24日 The crushing and grinding production line of sodium saltpeter usually includes multiple equipments, the following are some common equipments: Jaw Crusher: It is used for primary crushing of

Contact

Cement Extraction, Processing, Manufacturing

网页There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the

Contact

Lead-zinc ore crushing and grinding process mpl Ultrafine

网页2022年6月10日 The processing and production process of lead-zinc ore mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage closed-circuit crushing is a more modern method suitable for the crushing of high-hardness lead-zinc ore, which can complete the work of ore crushing and partial

Contact

Limestone crushing, sand making and grinding process

网页2022年7月20日 Limestone generally needs to undergo deep processing such as crushing, sand making, pulverization and grinding before it can be applied to all walks of life. Lime and limestone are widely used as building materials, most commonly as raw materials in the cement production process industry. At present, limestone mainly has crushing, sand

Contact

mpl Ultrafine Powder Technology Industrial Grinding Mill,

网页Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult. +8617821848717 [email protected] screening, grinding and other processing processes. This article mainly introduces the crushing and grinding equipment commonly used in the serpentine production line. GET

Contact

Crushing, Grinding and Reduction in Flour Milling

网页2016年11月2日 GRINDING CAPACITY Grinding capacity is calculated according to the factory's capacity. Crushing roller mill rolls should be up to approximately 40 percent of the total roller mill length, Reduction (liso) roller mill rolls are up to 60 percent of the total roller mill lenght. The average lenght of the roller mill is based on the account of12mm

Contact

marble crushing and grinding equipment in marble

网页2023年1月19日 marble crushing and grinding equipment in marble quarrying. Marble has excellent rigidity and becomes an important building material. Marble crushing and grinding equipment play an important role in the processing and the combination of them is the marble production line, which provides high quality marble material for building materials

Contact

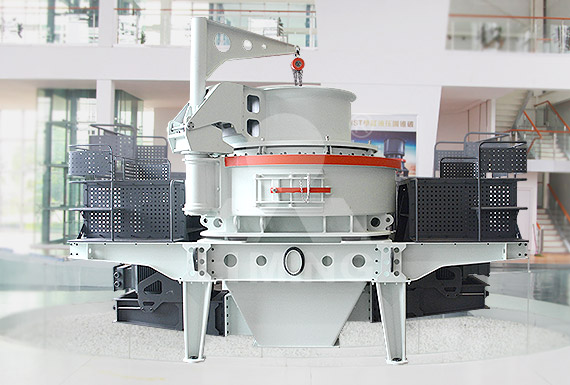

Serpentine crushing and grinding processing

网页2023年3月15日 This equipment is widely used in the crushing of various ores, the production of artificial sand and gravel in railway and construction industries. The serpentine crushed stone is further processed and

Contact

Eggshell Powder Making Machine

网页Eggshell needs to undergo a reasonable grinding process to further realize its higher economic value. It is very important to choose suitable grinding equipment and design a scientific production line process. The eggshell milling process is generally divided into two stages: crushing and grinding.

Contact

Gypsum crushing and grinding equipment SHANGHAI

网页2022年4月22日 Building gypsum powder production line is usually divided into gypsum mining process, crushing, grinding and calcining process according to technical requirements. Gypsum mining process Gypsum mining technology is divided into two categories: fibrous gypsum mining and alabaster, common gypsum, and anhydrite mining.

Contact

Limestone grinding process LinkedIn

网页2020年3月12日 Limestone is the main raw material for the production of cement, concrete aggregate, lime, etc. Crushing and grinding of limestone generally adopts the dry process, and the corresponding process

Contact

Slag grinding mill micro powder production line mpl

网页2022年5月12日 Mode 1: The drying and grinding steps are carried out separately. First, the materials are sent to the dryer for drying, and then the dried materials are sent to the ball mill to be ground into powder. Mode 2: Drying and grinding are carried out at the same time, the material is ground with a vertical micro-powder mill, and hot air is blown

Contact

Influence of Natural Aggregate Crushing Process on Crushing

网页2021年7月27日 Crushing is one of the most energy-consuming technological processes. The purpose of grinding is to achieve the desired grain size of mineral raw materials. The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the

Contact

Size Reduction of Solids Crushing and Grinding

网页The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology. It is estimated that mechanical size reduction of

Contact

Preparation Of Cement Raw Material Cement

网页The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing. Crushing: the limestone and other materials are crushed into small pieces by cement crusher,

Contact

(PDF) Overview of Mineral Processing Methods

网页2015年8月3日 Size reduction typically involved crushing, grinding, and screening (Balasubramanian, 2015) and various separation techniques were employed dependant on the mineral of interest.

Contact

Grinding (Comminution) an overview ScienceDirect Topics

网页The mill feed ore is sampled after a continuous process of systematic mixing, crushing, grinding, and pulverizing in the beneficiation plant. The fragment sizes have attained a best possible interlining homogeneity and uniformity at (−) 100 mesh size, and are collected by automatic sampler at 15/30 min intervals after ball/rod mills.

Contact

Available online at sciencedirect ScienceDirect

网页2021年8月9日 their main production process. The distribution of energy at a mine site is 3 5% for blasting, 5 7% for crushing, and 80 90 % for grinding [10, 11]. Energy consumption occurs everywhere in the mining and manufacturing sectors. For relevance in energy consumption, table 1 compares energy consumption for certain parts of the

Contact

Grinding, crushing Safe Food Factory

网页2018年3月8日 A whole range of grinding/milling techniques and equipment are available for application with different types of . Grinding/milling can be carried out dry or wet. In wet grinding/milling smaller particle sizes can be attained. Often dry grinding (milling) is combined with sieving or air classification, this results in particle size

Contact

(PDF) SIZE REDUCTION BY CRUSHING METHODS

网页2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Contact