المنتجات الساخنة

Comminution and classification technologies of iron ore

网页2022年1月1日 The unique feature of this type of devices is that the coarse ore particles themselves are used as the grinding media, not unlike a pebble mill in which the pebbles are generated naturally from the ore body.

Contact

Developments in iron ore comminution and classification

网页2015年1月1日 The unique feature of this type of device is that the coarse ore particles themselves are used as the grinding media, not unlike a pebble mill in which the pebbles

Contact

Research of iron ore grinding in a vertical-roller-mill

网页2015年3月15日 Overall, HPGR grinding is more beneficial to the quartz liberation, while ball mill grinding is more beneficial to oxidised iron minerals at a coarse grinding

Contact

Mineralogical characterization of the typical coarse iron ore

网页2019年1月15日 To decrease the energy consumption in grinding coarse iron ore particles, the preliminary processing of run-of-mine (ROM) iron ore has become necessary to

Contact

Mineralogical characterization of the typical coarse iron ore

网页2019年1月15日 The raw iron ore sample were initially coarsely crushed to the size fraction of −50 mm and then classified to various size fractions by using a set of sieves. The

Contact

Case Study of Dry HPGR Grinding and

网页2019年2月5日 High Pressure Grinding Rolls (“HPGR”) is applied in all stages of iron ore size reduction, from coarse ore grinding down to pellet feed preparation.

Contact

Research of iron ore grinding in a vertical-roller-mill

网页2015年3月15日 The application of vertical-roller-mills (VRM’s) for ore grinding is part of the second strategy. The grinding parts of a Loesche mill ( Fig. 1) are a rotating table (1) with

Contact

High pressure grinding moving ahead in copper,

网页This publication summarizes some of the features and experiences for recent applications in treatment of copper ore, coarse iron ore, and gold ore. Summary data of roll surface wear life and operating data are given,

Contact

Processing of Magnetite Iron Ores–Comparing

网页2009年1月1日 PDF Although the majority of current steel production is supported by iron ore sourced from high0grade haemetite deposits, the long-term growing Find, read and cite all the research you

Contact

Iron Ore Processing,Crushing,Grinding Plant

网页The coarse-grain permanent magnetic roller-type strong magnetic separator can obtain a coarse concentrate with an iron grade of 32% -34% and a tailing grade of 10%-12% under the conditions of a feed size of 20-2 mm

Contact

Research of iron ore grinding in a vertical-roller-mill

网页2015年3月15日 Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here. Within these test works, mill parameters like grinding pressure, separator speed

Contact

Extraction of Manganese and Iron from a Refractory Coarse

网页2021年3月30日 In this research, the coarse manganese concentrate was collected from a manganese ore concentrator in Tongren of China, and the contents of manganese and iron in coarse manganese concentrate were 28.63% and 18.65%, respectively. The majority of the minerals in coarse manganese concentrate occur in rhodochrosite, limonite, quartz,

Contact

Optimization of Solids Concentration in Iron Ore Ball

网页2019年6月18日 an iron ore from Brazil. The wet grinding experiments were conducted in bench (0.25 m diameter) and pilot-scale mills (0.42 m diameter), and surveys in a full-scale industrial (5.2 m diameter) mill. mill was described as a perfect mixed reactor that transforms coarse particles into smaller ones, in such a way that the particles feeding the

Contact

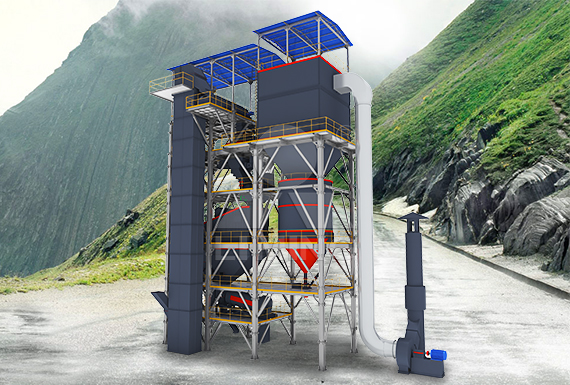

Lay-Out Example of Design for a "GrindX" Dry Iron Ore Grinding

网页High Pressure Grinding Rolls (“HPGR”) is applied in all stages of iron ore size reduction, from coarse ore grinding down to pellet feed preparation. In closed circuit operation, fine grinds

Contact

Vertical mill simulation applied to iron ores ScienceDirect

网页2015年4月1日 Abstract. The application of vertical mills in regrind circuits is consolidated. This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when compared to ball mills, which are usually used at this stage. In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit

Contact

id/iron ore grinding coarse.md at main sbmboy/id

网页印度尼西亚语的一些资料备份. Contribute to sbmboy/id development by creating an account on GitHub.

Contact

Optimization of Solids Concentration in Iron Ore Ball Milling

网页2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models. One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function. The stone demonstrates the application of this methodology to

Contact

Research of iron ore grinding in a vertical-roller-mill

网页2015年3月15日 The application of vertical-roller-mills (VRM’s) for ore grinding is part of the second strategy. The grinding parts of a Loesche mill ( Fig. 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring system.

Contact

VAN DER MEER, F.P.,LEITE, I.L. ENTMME

网页2015年11月9日 High Pressure Grinding Rolls (“HPGR”) are applied in all stages of iron ore size reduction, from coarse ore grinding down to pellet feed preparation. In closed circuit operation, fine grinds can be achieved using HPGR in combination with dry or wet classification or a partial product recycle without classification. For fine product cuts,

Contact

Investigation on Iron Ore Grinding based on Particle Size Distribution

网页2020年5月28日 The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore. Grinding experiments were conducted according to Bond’s standard test procedure [].For each iron ore sample, the RT taken to produce 250% circulating

Contact

Beneficiation of Gold and Silver Ores SpringerLink

网页2019年12月15日 Small media can still grind coarse feed because of its high speed up to 22 m/s. Figure 4.2 shows a detail schematic of a large IsaMill. The high-power intensity results in a small mill with short residence times less than a minute which avoids overgrinding. The ideal application is ahead of grinding and enhancing iron ore grinding and gold

Contact

Iron ore mineser.de

网页The dissociation during ore grinding is random. Dissociated ore under coarse grinding should be selected. By this process, select the dissociated coarse iron ore by gravity separation using spiral chute, then use high-efficiency and complex strong magnetic-anion reverse flotation process to get concentrate ore and discharge tailings.

Contact

Optimization of Solids Concentration in Iron Ore Ball Milling

网页2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models. One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function. The stone demonstrates the application of this methodology to

Contact

(PDF) Physicochemical Problems of Mineral

网页2017年3月20日 An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studied.

Contact

Iron Ore Processing, General SpringerLink

网页2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

Contact

THE EFFECTS OF PROCESS VARIABLES ON THE

网页The results of the analyses clearly shows that using a sieve of +180µm and its bottom -180µm, the best time for grinding 0.5kg of Itakpe iron ore with 3kg of grinding media and a mill speed of 92 rpm is 8 minutes, yielding

Contact

Reducing Grinding Energy and Cost Magnetite Iron

网页Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study A. Jankovic and W. Valery Metso Process TechnologyInnovation, PO Box 1028, Eagle Farm Qld, 4009, Australia

Contact

Impact of flotation operational parameters on the

网页2022年8月1日 An iron ore mineral processing plant in Brazil treating Itabirite ore was assessed by sampling a circuit consisting of Wemco 144 mechanical cells, as part of the AMIRA P9P collaborative research project. The head grade was 1.0% Cu, and the copper mineral was freed from encapsulation at a relatively coarse size. The initial grind size was

Contact

Comparative Analysis of Grindability of Iron‐ ore

网页2013年8月1日 The results obtained show that weight retained varies from 36.71 g to 183.1 g for granite while that of iron‐ore vary from 9.65 g to 87.78 g. In addition, it was observed that granite and iron

Contact